- Produits

- Catalogues

- News & Trends

- Salons

Variateur de fréquence IP20 triphasémonophasénumérique

Ajouter à mes favoris

Ajouter au comparateur

Caractéristiques

- Type

- triphasé, monophasé, numérique

- Montage

- à pose murale

- Applications produits

- industriel

- Indice de protection

- IP20

- Autres caractéristiques

- compact

- Puissance

Min: 0,37 kW

Max: 7,5 kW

Description

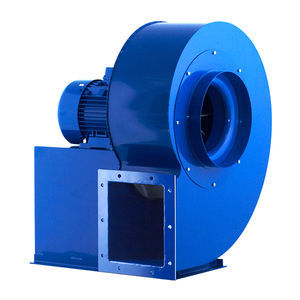

Ventilation, dust removal, and pneumatic waste transfer systems use fans, rotating machines, and high-vacuum units to generate the flow and pressure required for the network. Over time, these machines have become increasingly efficient, yields have improved, and the transmission between the electric motor and the turbine is direct. The pulley/belt devices used a few years ago are gradually disappearing.

Frequency inverters make it easy to adjust the rotation speed of the machines to just the right amount very quickly, without tools, thus replacing and eliminating the benefit of pulleys on rotating machines.

The frequency inverter also makes it possible to adjust the rotation speed of the fans to the process. When the process is discontinuous, the rotation speed of the fans is adjusted to the minimum during adjustment phases or between two production runs. The use is calibrated to the nominal value when the process is in normal operation.

Catalogues

Aucun catalogue n’est disponible pour ce produit.

Voir tous les catalogues de WattOhm* Les prix s'entendent hors taxe, hors frais de livraison, hors droits de douane, et ne comprennent pas l'ensemble des coûts supplémentaires liés aux options d'installation ou de mise en service. Les prix sont donnés à titre indicatif et peuvent évoluer en fonction des pays, des cours des matières premières et des taux de change.